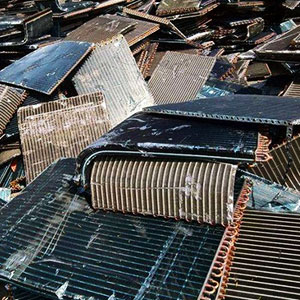

Large capacity waste copper auminum water tank radiator recycling system is specially designed for crushing scrap air conditioning radiator, and then separate copper, aluminum and iron for recycling. Having high automation and high efficiency, this radiator crushing machine is quite suitable for recycling large quantity of scrap radiators.

Capacity: 800~1500kg/h

Application: AC radiator recycling, water tank recycling

Large capacity radiator recycling system can process all kinds of large blocks of the radiator(copper and aluminum water box) or motor rotor(with axle)≤15cm. The equipment has features of the new design, nice appearance, unique and large capacity. Whole plant PLC controlling, one-time feeding, multi-machine cooperated processing; with automatic shutdown device and the overload automatic alarm device. The successful development of the processing line, greatly liberate the productive forces, improve the metal recycling quality. The most important, it solves the problem of dust overflow effectively, reducing the pollution to the air.

Put the material to the first crusher for the primary crushing and the crushed material conveying by the conveyor to the second grinder. The materials in the grinder will be crushed into the length of the 3cm. Then the materials went through magnetic separation to separate iron, then Gravity separation to separate the copper and aluminum. The whole production line is controlled by negative pressure and equipped with the pulse dust catcher to solve the dust problem.

The radiator and water tank recycling system consists of the following equipment:

1. Belt Conveyor: to connect the whole line and convey scrap radiators to crusher.

2. First Crusher (Double-shaft Crusher): to cut radiators into 10-20mm length, then the crushed material is transported by the conveyor belt to the second crusher.

3. Belt Conveyor: to transfer the first crushed materials for the second crushing.

4. Second Crusher: After transported to this crusher, the 10-20mm material is shredded by this crusher to smaller pieces.

5. Magnetic Separator: to separate iron from the crushed mixture, so that copper and aluminum can be separated easily.

6. Vibrating Separator: to separate copper pieces from aluminum pieces based on their different specific gravity.

1. Compared to Europe processing technology, our process has lower metal loss, we try to reduce the number of times materials being crushed, thereby reducing the generation of metal powder to improve recycling efficiency.

2. The first crusher designed by double roller and have the advantage of low noise and large torque,capable of crushing radiator in big size.

3. The blades of first crusher is made of alloy steel, with the special process makes the durable life longer than one year.

4. Using two times gravity separation, which improve the sorting accuracy.Sorting out of copper, aluminum, iron purity > 99%

5. With closed processing and dust collection system, which to effectively control the dust overflow.

| Model | Power (kw) | Capacity (kg/h) | Purity (%) | External dimension (mm) | Weight (kg) |

| SY-C-800 | 95 | 800-1000 | 99 | 14.8*3.8*4.2 | 8500 |

| SY-C-1000 | 135 | 1200-1500 | 99 | 16.8*3.8*4.5 | 10500 |

Please leave your contact information and requirements, so that our professional team can contact you ASAP.