E Waste Scrap Surface Metal Stripping Machine (gold deplating machine) is aimed at the gold stripping treatment of gold-plated materials in discarded electronic products.

Capacity:

Application: e waste gold recycling, surface precious metal recycling

E waste scrap surface precious metal stripping system was specially designed to strip gold from gold-plated materials that come from those obsolete and junked electronic products, which is currently the best gold extraction method. By using this system, the recovery rate of gold is up to 99%, and you can get high-purity gold after further refining.

Our Gold Stripping system applies to various gold-plated scraps generated in our daily life, such as waste cellphone circuit boards, computer CPUs, motherboards, VCDs, DVDs, TVs, game consoles, fax machines, telephone sets and many other old domestic appliances, as well as those leftovers and off-cuts from the electroplating factory, electronic components manufacturing factory, printing house.

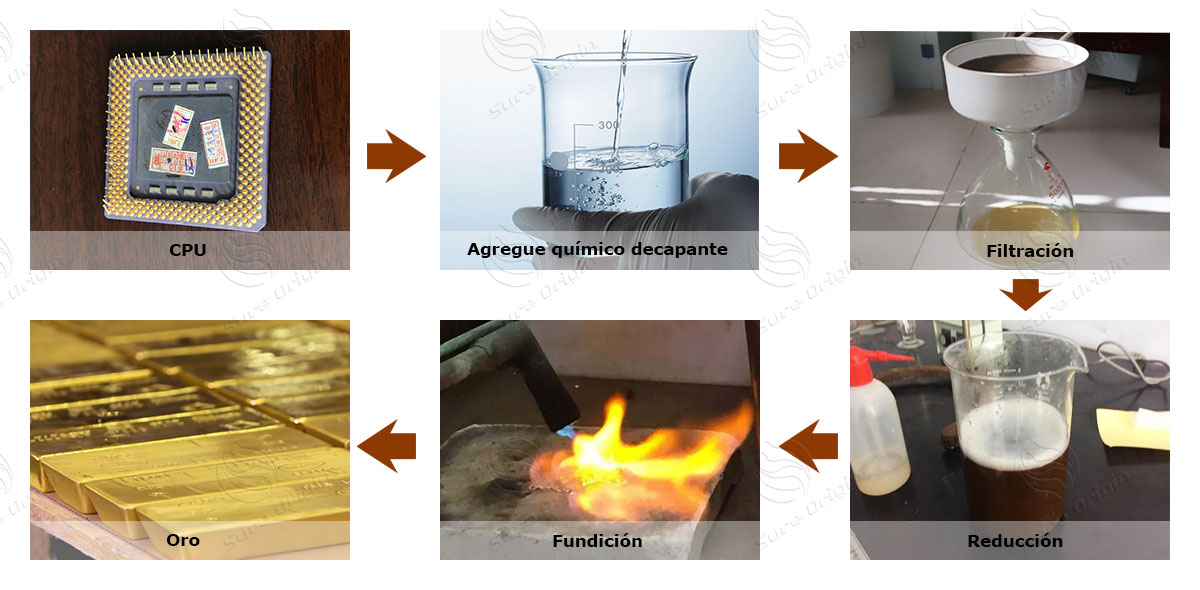

1. Dispensing the gold stripping solution;

2. Put the surface plated materials into liquid, then the surface gold dissolved in the gold stripping solutions, no other metal like lead, nickel, iron, or any other metal be dissolved in the solution. (our patent product);

3. Filtering to remove the impurity;

4. Reduction: Add the reduction powder to the solutions, the gold will be extracted and turn into black powder, Get the black powder settle down, then finally we get the crude gold powder.

1. The Deplating Agent Contains No Cyanide or Poisonous Substances.

2. Quick Deplating Speed, With An Average Rate Of 0.5-2 mm/min.

3. Stripping Is Accurate, And Gold Can Be Selectively Separated ,No Stain To The Nickel or Tin Layer.

4. High Efficiency With A Separation Rate of 99%, And High Gold Purity.

Please leave your contact information and requirements, so that our professional team can contact you ASAP.