The industrial double shaft shredder is designed for a wide array of applications and industries, suitable for shredding solid material such as E-waste, metal, wood, plastic, scrap tires, packaging barrel, pallets, etc.

Capacity: customized

Application: solid waste crushing and recycling

Industrial double shaft shredder to reduce material size by shearing, tearing, and squeezing. A industrial double shaft shredder is a machine that is used as a fine crusher and is generally used to process unprocessed raw materials or scraps to make them smaller in size. Widely used in waste plastics, waste rubber, waste tires, scrap cars, waste newspapers, waste books, wood, paint buckets, discarded home appliances (plastic shells, metal shells), used circuit boards (circuit boards), used cables and other Large volume of waste.

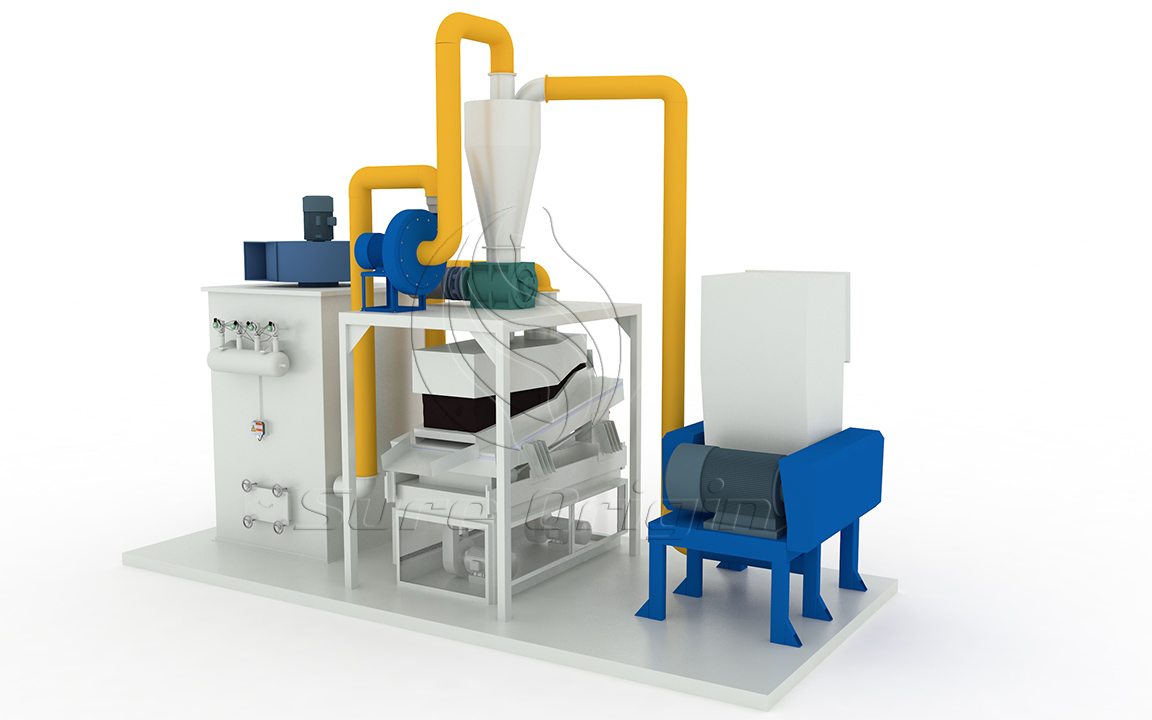

Main structure of industrial double shaft shredder includes shaft, moving blades, fixed blades, reducer, motors, feeding hopper, discharge port, electric control cabinet,control panel,screen, roller, knives holder, ect.

We design the blades with different hooks, and the thickness of blades for different materials are different, the range is 10mm-80mm. Blade quality have 9CrSi, Cr12MoV, SKD-II, D2 etc. The fixed knife is patent-hooked to optimize the tool change function, making tool maintenance replacement more efficient.

The main body of the shredder is welded with high quality steel plate to eliminate stress treatment/integral machining to ensure the stability of the equipment under heavy load for a long time. The crushing room use noise arrester, to lower noise. Crushing room materials is high quality steel, rigid reasonable and durable.

Knife shaft is is made of special special alloy tool steel forging blank, precision machining, multiple heat treatment and low temperature freezing heat treatment technology, and reasonably provided powerful power for cutting.

1. Heavy-duty construction and efficient performance are determined by the precisely processed combined frame made of extra-thick plates

2. Wide angle, hexagon prism of power slewing axis; large hopper with big caliber for feeding large material

3. It adopts PLC control system, automatic overload protection and auto reverse switch

4. The low rotation speed results in a particularly quiet shredding process with low levels of dust generation

5. It can be adjusted according to customer specific requirements for throughput volume, material to be processed, etc.

| Model | Dimension | Power | Capacity | weight |

| SY-CD-600 | 2*1.2*1.6m | 18.5kw | 1000kg/h | 2000kg |

| SY-CD-800 | 2.5*1.35*1.8m | 18.5kw * 2 | 1000 ~ 2000kg/h | 3800 ~ 4000kg |

| SY-CD-1000 | 3.3*1.9*2.2m | 30kw * 2 | 3000kg/h | 5200kg |

| SY-CD-1200 | 3.6*2*2.2m | 37kw * 2 | 4000 ~ 5000kg/h | 6400kg |

Please leave your contact information and requirements, so that our professional team can contact you ASAP.