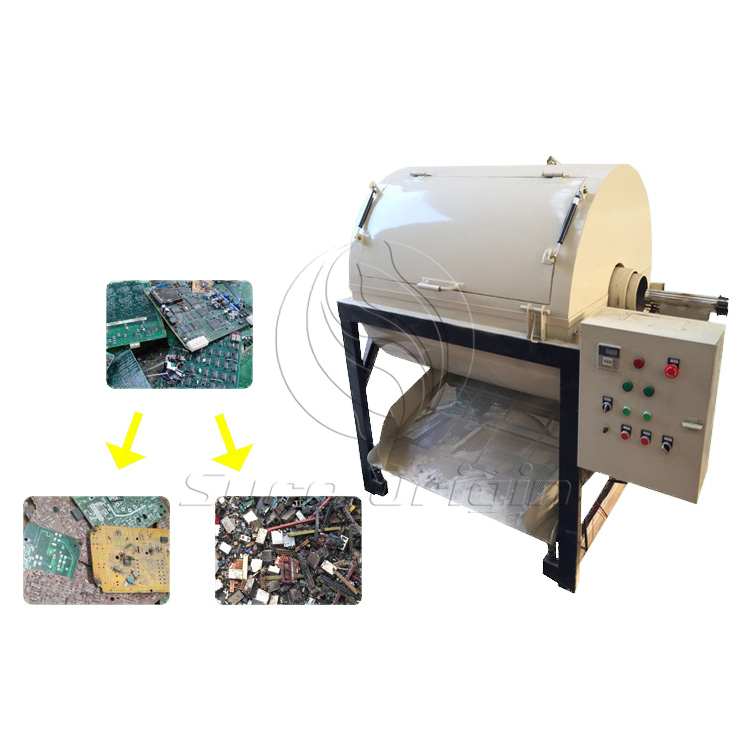

A few days ago, our company alibaba website received an inquiry from an American customer, the product he wants is PCB separator dismantling machine. As soon as we receive the inquiry, we will reply to the customer and inform him that we have PCB dismantling machine. After preliminary understanding, it turned out that the customer from America was a manager of a small recycling factory, and his materials were some PCB electronic components, circuit boards and so on. We then sent him the product catalog of our company for his further understanding. During this period, our salesman kept good communication with him. If there are any questions, we will answer them immediately. The customer was satisfied with our machine and wanted to order one quickly. In the end, the customer chose a medium-sized PCB recycler capable of processing 200-300 KGS PCB boards per hour. The PCB dismantling and recycling machine consists of two parts. One is a PCB disassembler, which removes electronic components from a PCB board. The other is the PCB recycling line, which pulverizes the PCB board to separate the copper metal from the resin fiber. Now the goods are in the factory ready to be sent to the port and shipped to the customer's country by sea.

The PCB disamntling seperator machine was purchased by a customer in the United States, who purchased the machine mainly for processing PCB circuit boards. The PCB separation equipment features: 1. Compact structure, reasonable layout, stable performance, low noise. 2. Adopt PLC to control the whole production line for uniform feeding and coordinated operation. 3. Adopt two level grinding, so that the processing capacity can reach 300KG per hour.

Please leave your contact information and requirements, so that our professional team can contact you ASAP.